Uniflow technology really comes into its own when used in industrial cooling technology. as a result, Uniflow is currently being used in pump systems in particular, with less focus on cooling systems based on direct expansion (DX).

the high level of performance delivered by Uniflow is not dependent on whether a cooling system is sub- or transcritical. however when choosing the right size Uniflow, temperature is obviously an important factor.

the performance of Uniflow droplet separation is the same regardless of the refrigerant used, making the droplet separator suitable for a range of applications. Uniflow can be used as a pump container, racing vessel, chiller, economizer or intercooler.

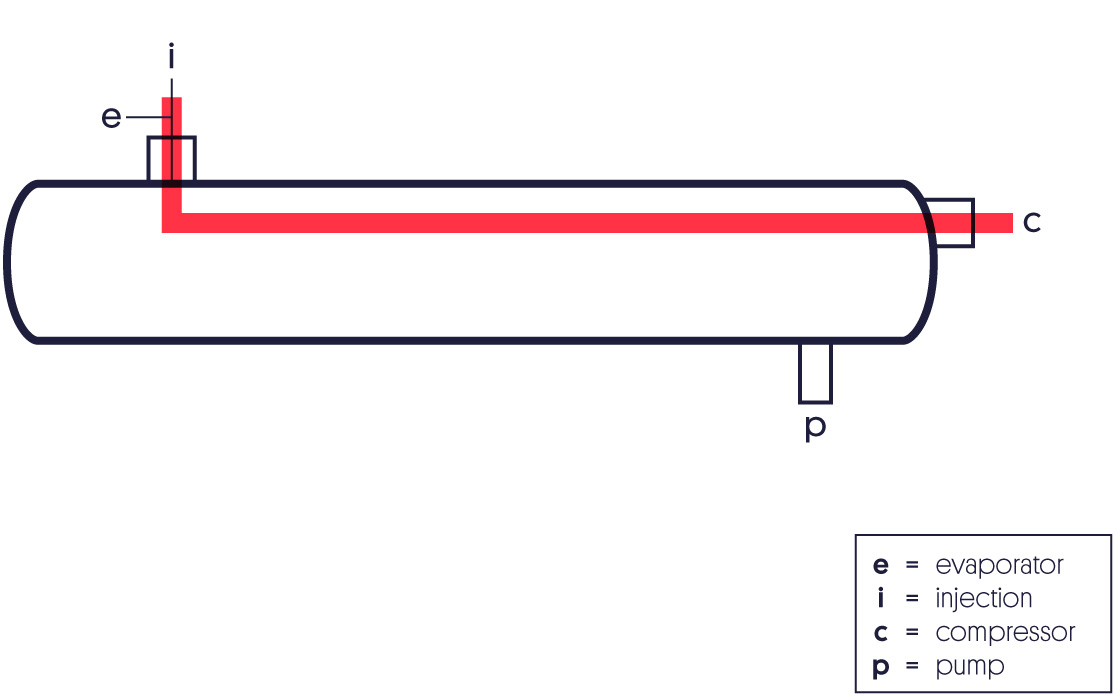

the simplest use of Uniflow is as an individual droplet separator and accumulator. There is a range of vessels of increasing capacity that can be used for this application. The design is standardized. You can easily calculate the most suitable solution for your system using the calculation tool on this site. Droplet separation with Uniflow delivers 99.99% dry gas – whatever the refrigerant used.

calculate

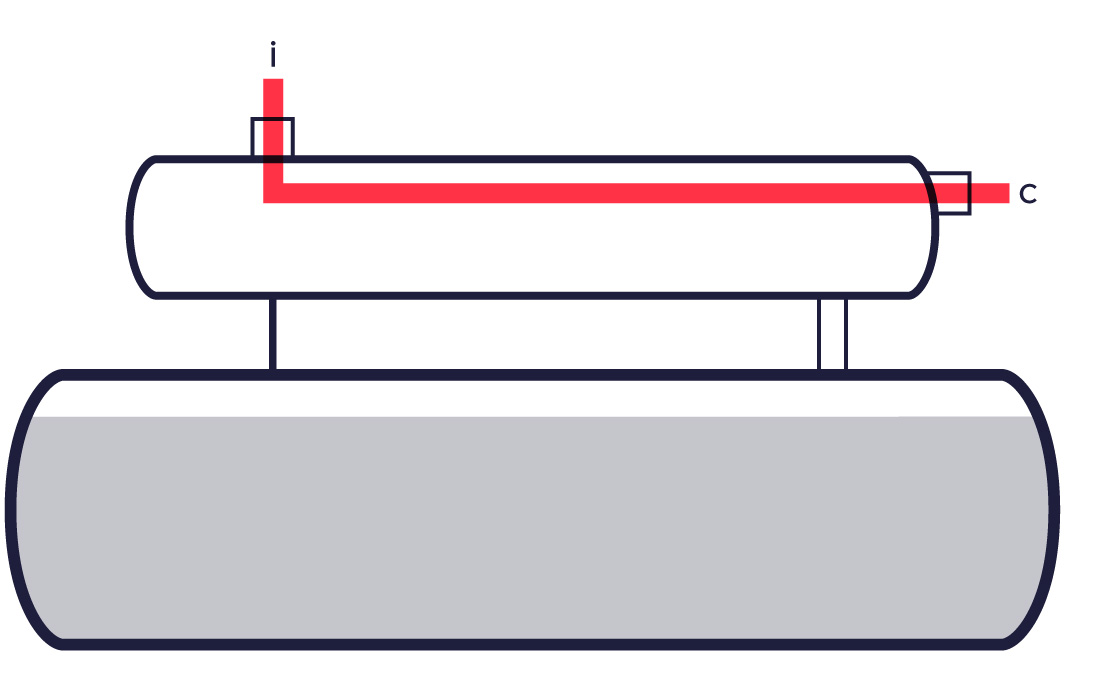

the unique Uniflow technology enables the gas to pass through the droplet separator at a high flow rate, creating a high capacity in a relatively small vessel. separation without a buffer volume makes optimum use of the system. Uniflow can be used effectively as a racing vessel for expanding an existing cooling system or when carrying out a retrofit. the old separator can serve as a buffer vessel while a small Uniflow can be installed to provide unprecedented efficient droplet separation.

calculate

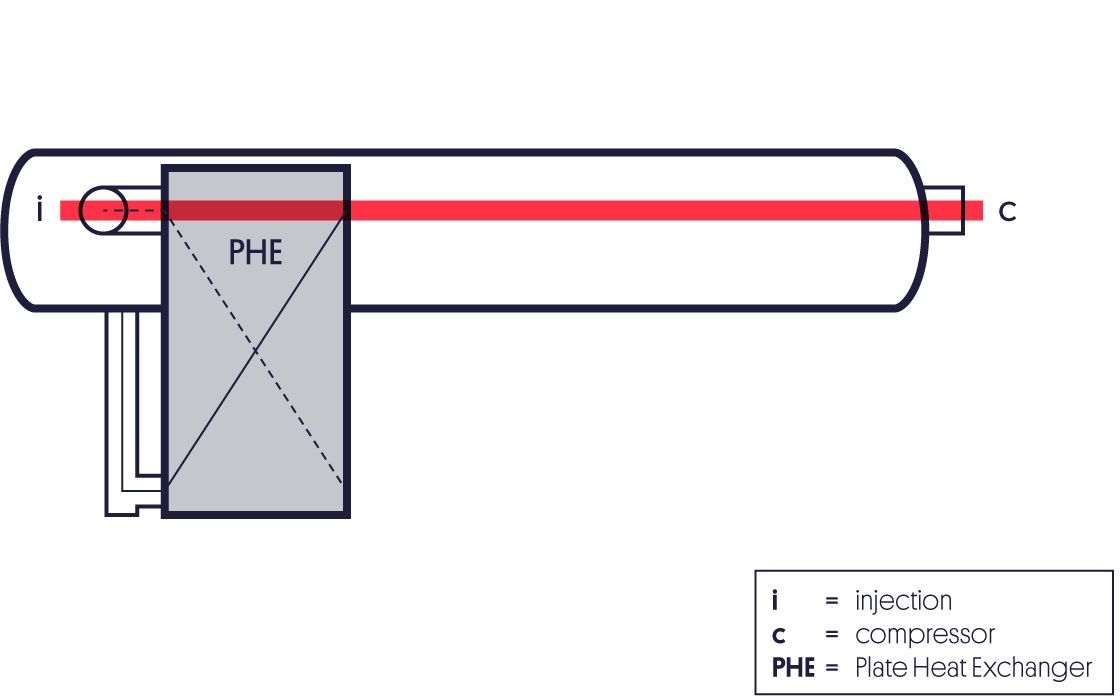

Uniflow separation technology can easily be combined with plate heat exchangers to create a chiller. For the Unilaval system, the design of the vessel was adapted to take into account the connection to the heat exchangers. With this, the separator is positioned next to, or possibly between, a number of plate heat exchangers.

This combination, which is particularly easy to control, works with an exceptionally low refrigerant charge, has a low overall height and has a much higher partial load COP of approximately 7% because the exchanger is not operating fully charged.

Unilaval is available in standard sizes but larger or adapted designs can also be produced.

calculate

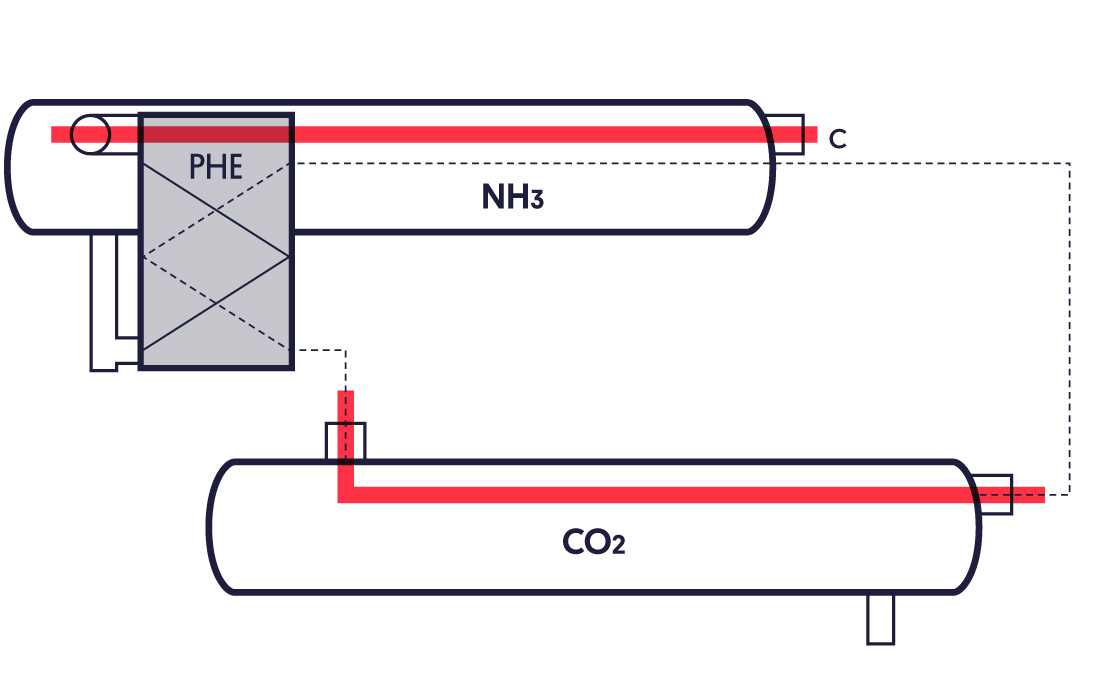

Uniflow can be installed in two places in NH3/CO2 cascade systems so that you can enjoy double the benefit with this highly efficient droplet separation in your cooling system. On the NH3 side, the chiller – such as the Unilaval, for example – delivers optimum performance when Uniflow is installed while on the CO2 side, the system benefits from Uniflow once again in the form of a simple pump container. The calculation tool on this site makes it easy for you to calculate, select and order both options.

calculate

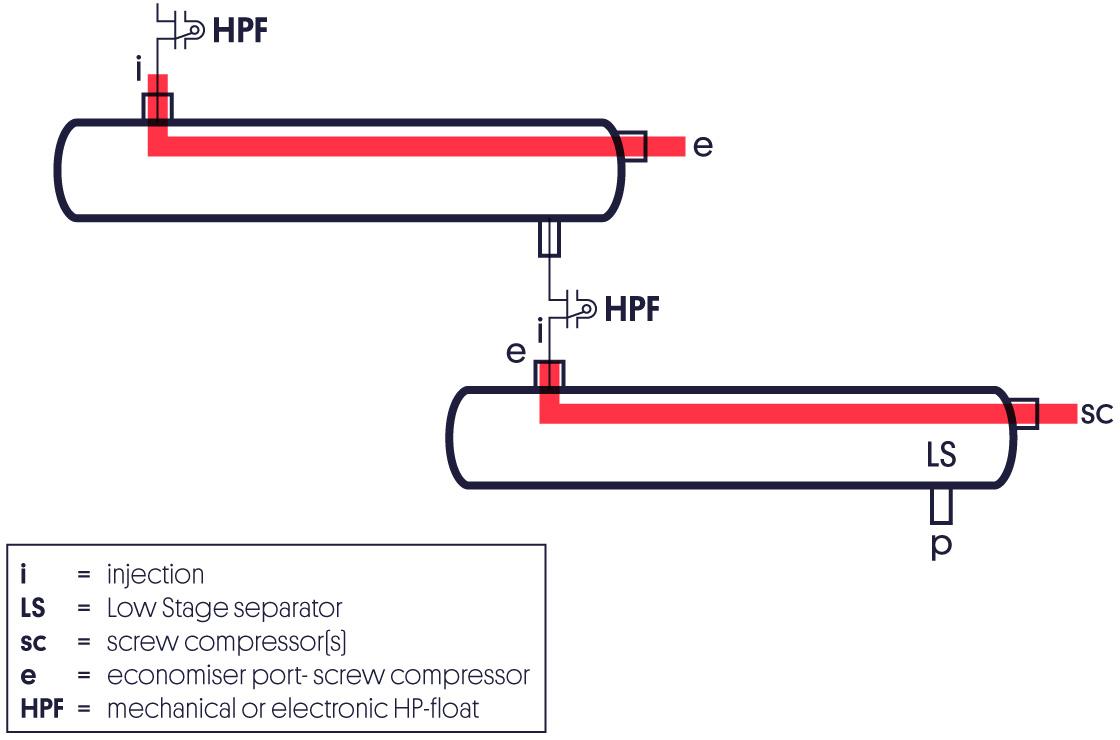

Uniflow also comes into its own as an economizer. use the efficient technology for expanding the condensate in two stages and for producing real droplet-free flash gas that can be directed to the eco-port of the screw compressor. use the calculation tool to quickly and easily calculate, select and request a quotation for the Uniflow that is right for you.

calculate

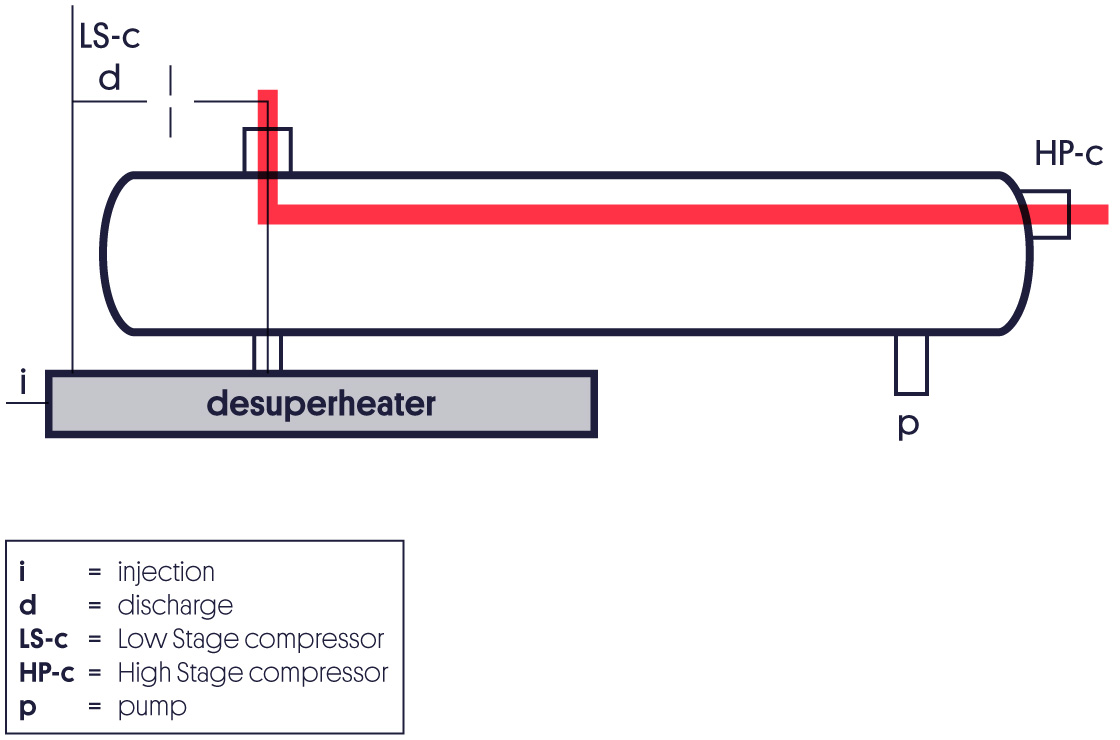

Uniflow can also serve as an open flash intercooler for cooling the compressed gas from the low-pressure compressor almost to saturation temperature and letting the condensate from the condenser expand in a two-stage process. and naturally for supplying the droplet-free vapor to the high-pressure compressor. use the calculation tool to quickly and easily calculate, select and request a quotation for the Uniflow that is right for you.

calculate