Uniflow is the high-performance droplet separation technology which delivers 99.9% dry gas and is suitable for use with any refrigerant. The unique design of the horizontal droplet separator ensures the uniform flow rate of the gas to be dried. It is that uniform flow which ensures that the gas is properly dry.

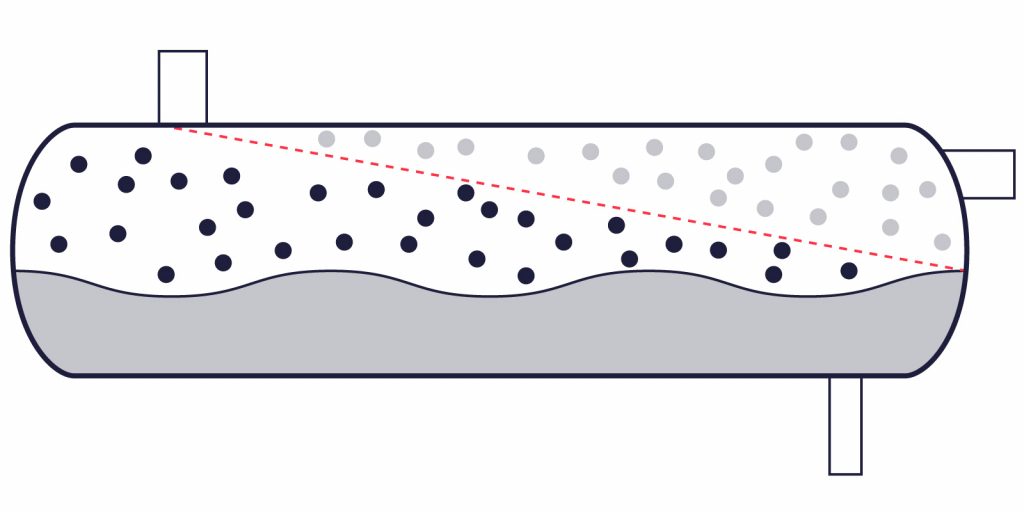

a droplet is separated when it reaches ‘the bath’.

This theory is based on the assumption that a droplet falls at a speed Ut under the influence of gravity. The fall time is determined by the fall height, Hsep. (Droplet fall time = Hsep/Ut) The gas velocity is Ug while the horizontal distance that the droplet travels before being absorbed by the surface of the liquid is Lsep. (Droplet retention time is Lsep/Ug.)

Based on this formula, you would have to extract all the droplets from the gas. However, the maximum achievable result is 98% dry gas – or 2% wet gas.

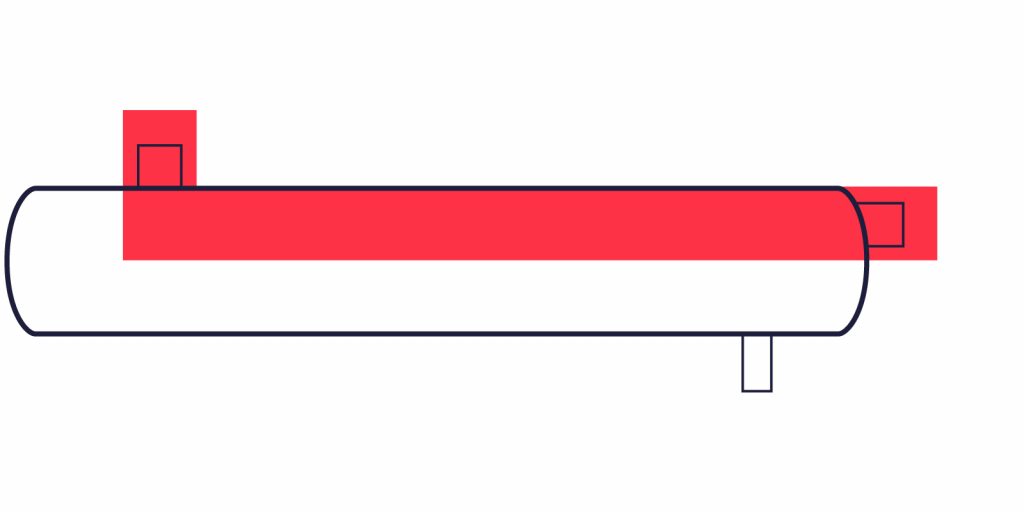

research into conventional droplet separation technology showed Prevesco that in order for droplet separation to be efficient, a uniform gas flow is required. It is also important to know how the return gas is spread across the gas segment. We developed a maintenance-free distribution mechanism which ensures a uniform gas flow. With this, droplet separation is 100 times more efficient than in previous droplet separators, reducing the content of harmful moisture in the compressor significantly and compressing the drier gas more effectively. A double benefit in terms of efficiency.

for a long time, separation technology was based on models with uncertainties, averages and assumptions when calculating the moment of separation. Models which were also heavily influenced by design limitations, conditions and the refrigerant used. As a result, the gas was never drier than 98%. The remaining moisture content – equivalent to a rain shower – constantly attacked the system. In order for the system to work safely, an overload of additional safety features had to be built in.

calculate